CNC Machining Aluminium Turning Parts Plated Black Oxide

Overview Customer Visit Our Services1. Professional Manufacturer: All of our Fastener are designed and manufactured acco

Description

Basic Info

| Model NO. | ST919610336 |

| Finish Color | Yellow, Red, Silver, Gold, Blue, Black, Natural |

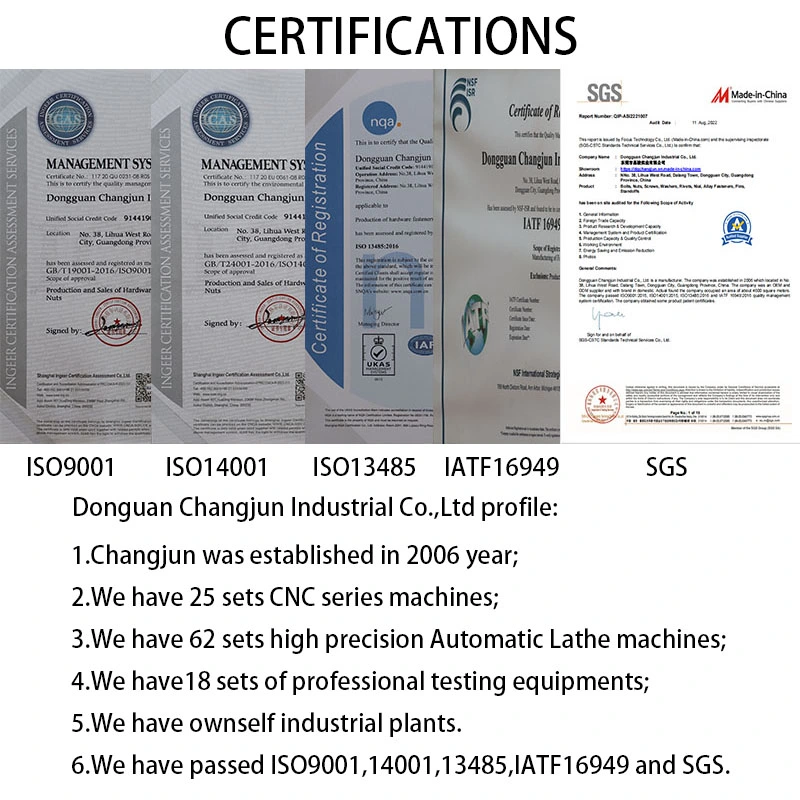

| Certifications | ISO9001, ISO14001, ISO13485, SGS, IATF16949 |

| Quality Control | 100% Inspection Berore Shipment |

| Tolerance | ±0.005mm |

| Transport Package | Small PE Bag/Blister Tray /SMT Tape +Carton+Pallet |

| Specification | Customer designation |

| Trademark | CJSY |

| Origin | China |

| HS Code | 7318160000 |

| Production Capacity | 100ton/Month |

Product Description

| Product Name | thru-hole CNC turning parts |

| Design/Size | According to custom's drawing or sample. |

| Surface Treatment | Zinc Plated (Yellow,Clear,Blue,Black), Anodize(Black, Gold, Natural), Copper Red, Copper Yellow, Sandblast and Anodize, Nickel Flash, Chrome Flash, Nickel Electroless, Tin Flash, Passivaton, Electro Painting etc. |

| Customized ProductsLead time | 3-7working days for samples generally, mass production within 15 working days. |

| Test Equipments | Automatic screening machine, Nut sorter, 2D&3D Projector,Vicker Hardness Tester, Calipers, Pin Gauge,Salt Spray Test Machine,ROHS & Film thickness test machine, Push/Tensile machine, Installation Machine, Torquemeter, Magnifier |

| Shipping | By sea, by air, International Express(DHL,FedEx,TNT,UPS) |

| Packing | Small PE Bag/Blister Tray /SMT tape +Carton +wood pallet or according to customer requirements. |

| payment | Advanced payment of 30% as down payment,the balanced will be paid off before shipping. |

FAQQ1:Can I get a sample before mass production?A1: We can provide free sample if we have this in stock, as long as you afford the freight. If no stock,we can produce foryou after get sample fee. lead time: 5-7 working days.Q2:What is the lead time of the mass production?A2: Normally 7-15 working days, it depends on the quantity.

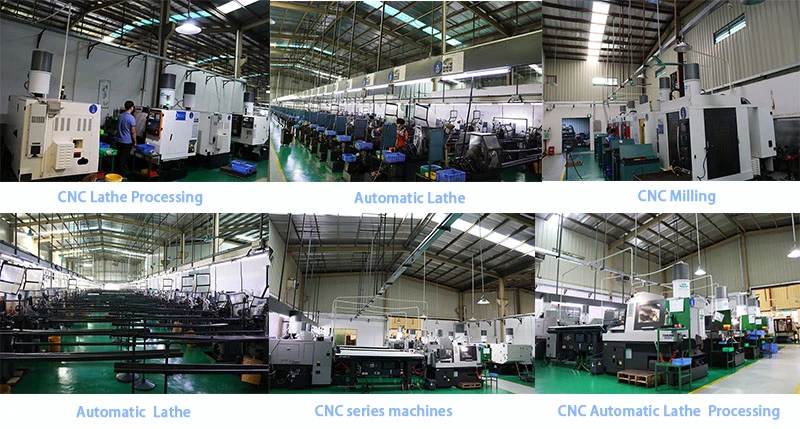

Q3:How to guarantee the Quality of Industrial Parts?A3: We have been in fastener field over ten years with full experience. And there are 5 checks in the whole processing,We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) , OQC (out-going quality control) and full inspection to control each process of industrial parts production.Q4:What are our machining equipment?A4:CNC milling machines, CNC turning machines, stamping machines,grinding machines,automatic lathe machines, tapping machines, grinding machines,screw machines, cutting machines and so on.Q5:Will my drawing be safe after you get it?A5: Yes, we will not release your design to third party unless with your permission.

Our Contact

Send now